ATA QBLV10 Series Low Voltage Variable Frequency Drive

Current vector control

Wide speed range

Adaptive acceleration and deceleration

No impact speed tracking

The ATA QBLV10 series standard frequency inverter is a high-performance inverter that integrates vector frequency conversion technology, which can easily drive induction motors with its high-performance current vector technology. This product features a high-performance, high-quality, and high-power density design, significantly enhancing usability, maintainability, environmental friendliness, installation space, and design standards, further enhancing the user experience.

Classification:

Low Voltage Variable Frequency Drive

Key words:

Product Consulting

Product Details

Specifications

Application areas

◆ Current Vector Control

Adjust motor parameters online according to the motor's operating status to achieve optimal control of the motor.

◆ Large Speed Range

Output frequency 0 to 3000Hz.

◆ Adaptive Acceleration and Deceleration

Intelligently adjust the acceleration and deceleration rates based on the load operating status.

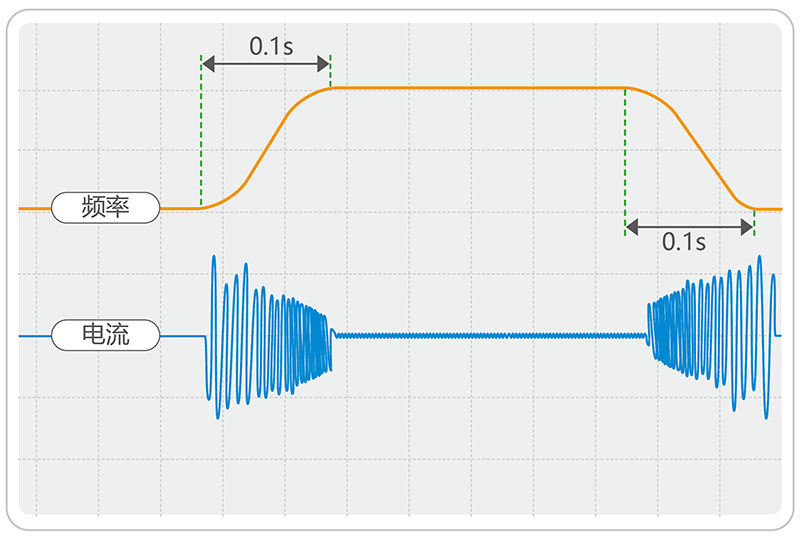

◆ Excellent Acceleration and Deceleration Performance

Outstanding current and voltage control technology, alternating acceleration and deceleration with a command of 0.1s, ensuring stable and jump-free operation of the inverter.

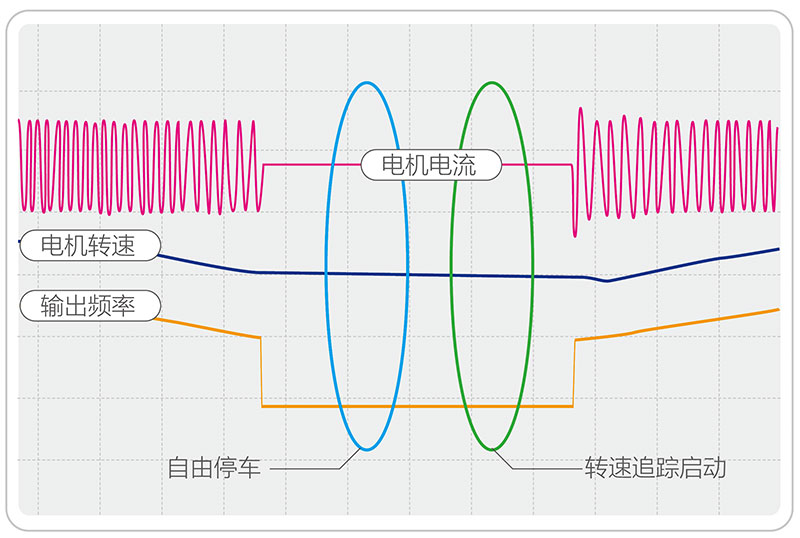

◆ No-impact Speed Tracking

No need for dedicated hardware detection circuits; the inverter completes the identification of motor speed, direction, and phase angle within 0.2s, smoothly tracking the start of a freely rotating motor.

◆ Instant Power Loss, Continuous Operation

During instantaneous power loss in the grid, the energy fed back from the motor allows the inverter to continue operating without stopping until the power supply returns to normal.

◆ Direct Switching Performance

Excellent current limiting performance allows the inverter to connect or disconnect the motor at will while in operation.

◆ Intelligent Flux Braking

Intelligently determine the strength of flux braking based on the motor's operating status, minimizing deceleration time.

◆ Communication and Networking

Adopts the internationally standard MODBUS communication protocol, facilitating complete network control with PLCs, touch screens, etc.

◆ Intelligent Energy-saving Operation

Intelligently determine the energy-saving strength based on the motor's operating status, minimizing energy consumption during motor operation.

◆ Modular, Flexible, Highly Adaptable

Utilizes a modular design concept to provide users with various general application controls; the output capability of ATA QBLV10 has been proven to meet the requirements of the vast majority of industrial controls.

◆ Full-domain DC Braking

DC braking can be activated from any frequency without a deceleration process.

◆ Rich Hot-swappable Options

Directly hot-swappable RS485 communication expansion cards and operation panels.

Model Parameters

| Inverter Model | Installation Hole Position (mm) | Dimensions (mm) | Installation Hole Diameter d/D1 (mm) | Weight (KG) | ||||||

| A1 | A2 | B | B1 | H | H1 | W | D | |||

| ATA QBLV10-H-4T0.4GB | 74 | 71.5 | 187 | 4.6 | 198 | 184 | 90 | 139 | 5 | 1.5 |

| ATA QBLV10-H-4T0.75GB | ||||||||||

| ATA QBLV10-H-4T1.5GB | ||||||||||

| ATA QBLV10-H-4T2.2GB | ||||||||||

| ATA QBLV10-H-4T3GB | ||||||||||

| ATA QBLV10-H-4T4GB | ||||||||||

| ATA QBLV10-H-4T5.5GB | 90 | 90 | 190 | 5 | 202 | 202 | 102 | 162 | 6 | 2 |

| ATA QBLV10-H-4T7.5GB | ||||||||||

| ATA QBLV10-H-4T11GB | 147 | 147 | 278.5 | 7.3 | 297 | 297 | 165 | 207 | 7 | 5.5 |

| ATA QBLV10-H-4T15GB | ||||||||||

| ATA QBLV10-H-4T18.5GB | ||||||||||

| ATA QBLV10-H-4T22GB | 160 | 383 | 8.5 | 400 | 380 | 205 | 223 | 8 | 17 | |

| ATA QBLV10-H-4T30GB | ||||||||||

| ATA QBLV10-H-4T37GB | ||||||||||

| ATA QBLV10-H-4T45G | 176 | 544 | 12 | 560 | 534.5 | 261 | 324 | 8 | 26 | |

| ATA QBLV10-H-4T55G | ||||||||||

| ATA QBLV10-H-4T75G | ||||||||||

| ATA QBLV10-H-4T90G | 195 | 615 | 15 | 638 | 610 | 275 | 364 | 8 | 36 | |

| ATA QBLV10-H-4T110G | ||||||||||

| ATA QBLV10-H-4T132G | 220 | 987 | 13 | 1120.5 | 1012.5 | 354 | 380 | 10 | 65 | |

| ATA QBLV10-H-4T160G | ||||||||||

| ATA QBLV10-H-4T185G | ||||||||||

| ATA QBLV10-H-4T200G | 218 | 1089 | 17.5 | 1234.5 | 1126.5 | 354 | 430 | 14 | 95 | |

| ATA QBLV10-H-4T220G | ||||||||||

| ATA QBLV10-H-4T250G | ||||||||||

| ATA QBLV10-H-4T280G | 218 | 1221.5 | 17.5 | 1367 | 1259 | 361 | 550 | 14 | 135 | |

| ATA QBLV10-H-4T315G | ||||||||||

| ATA QBLV10-H-4T355G | ||||||||||

| ATA QBLV10-H-4T400G | 218 | 1366.5 | 25 | 1527 | 1419 | 364 | 562 | 18 | 210 | |

| ATA QBLV10-H-4T450G | ||||||||||

Technical Specifications

| Function Description | Specification Index | |

| Basic Functions | Maximum Frequency | Vector Control: 0 ~ 300Hz V/F Control: 0 ~ 3000Hz |

| Carrier Frequency | 1kHz ~ 16kHz Carrier frequency can be automatically adjusted according to load characteristics | |

| Input Frequency Resolution | Digital Setting: 0.01Hz Analog Setting: Maximum Frequency × 0.01% | |

| Control Method | Open Loop Vector Control (SVC) V/F Control | |

| Starting Torque | 0.5Hz/150% (SVC) | |

| Speed Range | 1:100 (SVC) | |

| Speed Stability Accuracy | ±0.5% (SVC) | |

| Overload Capacity | G Type Machine: 150% rated current for 60s; 180% rated current for 1s | |

| Torque Boost | Automatic torque boost; manual torque boost 0.1%~30.0% | |

| V/F Curve | Three types: Linear; Multi-point; Nth Power V/F Curve (1.25 power, 1.5 power, 1.75 power, 2 power) | |

| Acceleration and Deceleration Curve | Linear or S-curve acceleration and deceleration method. Four acceleration and deceleration times, with a range of 0.05S~600.0Min | |

| DC Braking | DC braking frequency: 0.00Hz~ Maximum Frequency Braking Time: 0.0s~30.0s Braking Action Current Value: 0.0%~150.0% | |

| Jog Control | Jog Frequency Range: 0.00Hz~50.00Hz Jog Acceleration and Deceleration Time: 0.05S~600.0Min | |

| Simple PLC, Multi-segment Speed Operation | Achieve up to 16 segment speed operation through built-in PLC or control terminals | |

| Built-in PID | Conveniently implement process control closed-loop control system | |

| Automatic Voltage Regulation (AVR) | Can automatically maintain constant output voltage when the grid voltage changes | |

| Overvoltage and overcurrent stall control | Automatically limit current and voltage during operation to prevent frequent overcurrent and overvoltage tripping | |

| Torque limitation and control | Excavator characteristics, automatically limit torque during operation to prevent frequent overcurrent tripping | |

| Instant stop without stopping | Compensate for voltage drop during instantaneous power failure by feeding back energy from the load, allowing the inverter to continue running for a short time | |

| Bus support | Supports RS485 field bus: Modbus-RTU | |

| Operation and protection | Command source | Operation panel setting, control terminal setting, serial communication port setting Can switch through multiple methods |

| Frequency source | 11 types of frequency sources: digital setting, analog voltage setting, analog current setting, pulse setting, serial port setting. Can switch through multiple methods | |

| Input terminals | 8 digital input terminals, of which 1 supports high-speed pulse input up to 100kHz 2 analog input terminals, supporting 0 to 10V voltage input or 0 to 20mA current input | |

| Output terminals | 1 high-speed pulse output terminal, supporting square wave signal output of 0~100kHz 2 relay output terminals 2 analog output terminals, supporting 0~20mA current output or 0~10V voltage output | |

| Protection functions | Input and output phase loss protection, overcurrent protection, overvoltage protection, undervoltage protection, overheating protection, overload protection, etc. | |

| Display and accessories | LED display | Display parameters |

| Parameter copy | Parameters can be quickly copied through the operation panel | |

| Optional accessories | RS485 communication card, etc. | |

Environment

| Usage location | Indoors, not exposed to direct sunlight, free from dust, corrosive gases, flammable gases, oil mist, water vapor, dripping water or salt, etc. |

| Altitude | Below 1000m (must derate when altitude exceeds 1000m) | |

| Ambient temperature | -10℃ ~ +40℃ (if ambient temperature is between 40℃ ~ 50℃, please derate usage) | |

| Humidity | Less than 95%RH, no water droplet condensation | |

| Vibration | Less than 5.9m/s2 (0.6g) | |

| Storage temperature | -20℃ ~ +60℃ | |

| IP rating | IP20 | |

| Pollution level | PD2 | |

| Power distribution system | TN, TT | |

Air compressors, central air-conditioning, water pumps, textiles, plastics, ceramics, mining, conveyors, centrifuges, grinders, saws, metal processing, packaging machinery, elevators and escalators, pharmaceuticals, leather machines.

Product recommend

<div class="sy"> <P>Diversified start and stop modes</P> <P>Multiple user interfaces</P> <P>Perfect protection function</P> <P>Powerful memory function</P> </div> <div class="ny"> <P>The ATA QB-7 series motor soft starter is a new type of device that integrates power electronics technology and the latest motor control theories. It can be widely used in loads such as fans, water pumps, compressors, and ball mills, making it an ideal replacement for traditional starting devices like autotransformer reduced voltage starters, star-delta starters, and magnetic control reduced voltage starters.</P> </div>

ATA QB-H Series Medium Voltage Soft Starter

The ATA QB-H series medium voltage soft starter device combines computer control technology with power electronics technology, using high voltage high power thyristors as the main switching components in the circuit. By changing the conduction angle of the thyristors, it controls the smooth rise and fall of the motor voltage and achieves contactless on-off, enabling smooth start and stop of the motor. It starts the motor with an ideal current, effectively reducing the impact on the power grid, lowering equipment vibration, noise, and starting mechanical stress, thereby extending the service life of the motor and related equipment.

ATA QB-S Series Medium Voltage Soft Starter

The ATA QB-S series medium voltage electric motor solid-state soft starter device achieves a perfect integration of the switch cabinet and soft starter. It is designed to match the most demanding industrial requirements with compact size, flexible input and output line configurations, a modular silicon box design, a brand new electronic PT sampling feedback system, and easy operation and maintenance.

GKGR Series General Mining Medium Voltage Soft Starter

<div class="sy"> <P>Multiple security protection(up to 9)</P> <P>Compatible with various installation environments</P> <P>High protection level(for cabinet):IP54</P> <P>Flexible starting modes</P> </div> <div class="ny"> <P>The GKGR series mine general medium-voltage soft start control cabinet adopts DSP control technology. During startup, it detects current and power factor, controls output voltage, and reduces starting current to ensure smooth motor startup. Upon stopping, it controls output voltage and gradually decreases running current for a smooth motor stop. This effectively reduces the starting impact current of the motor, minimizes the impact on the power grid, and also reduces the mechanical impact force on the mechanical load devices connected to the motor, extending the equipment's lifespan and lowering the later operational and maintenance costs. The product also features protection functions against overload, three-phase imbalance, phase loss, undervoltage, starting overcurrent, and starting timeout faults. It is mainly suitable for the control and protection of starting, running, and stopping large power asynchronous or synchronous motors.</P> </div>

Product recommend

Diversified start and stop modes

Multiple user interfaces

Perfect protection function

Powerful memory function

The ATA QB-7 series motor soft starter is a new type of device that integrates power electronics technology and the latest motor control theories. It can be widely used in loads such as fans, water pumps, compressors, and ball mills, making it an ideal replacement for traditional starting devices like autotransformer reduced voltage starters, star-delta starters, and magnetic control reduced voltage starters.

Product Consulting

After receiving your information, we will get in touch with you as soon as possible.